It all started when Mr. Rajeev, a third-generation entrepreneur running a sports equipment manufacturing unit in Coimbatore, was facing a recurring challenge. His company supplied automated goalpost systems, retractable cricket nets, motorized basketball hoops, and stadium seating platforms to schools, stadiums, and sports clubs across India.

But there was one problem.

The older systems used hydraulic and pneumatic mechanisms. They were bulky, prone to oil leaks, noisy, and needed frequent maintenance. For high-traffic grounds where quick setup and safety were non-negotiable, these old systems were holding Rajeev back.

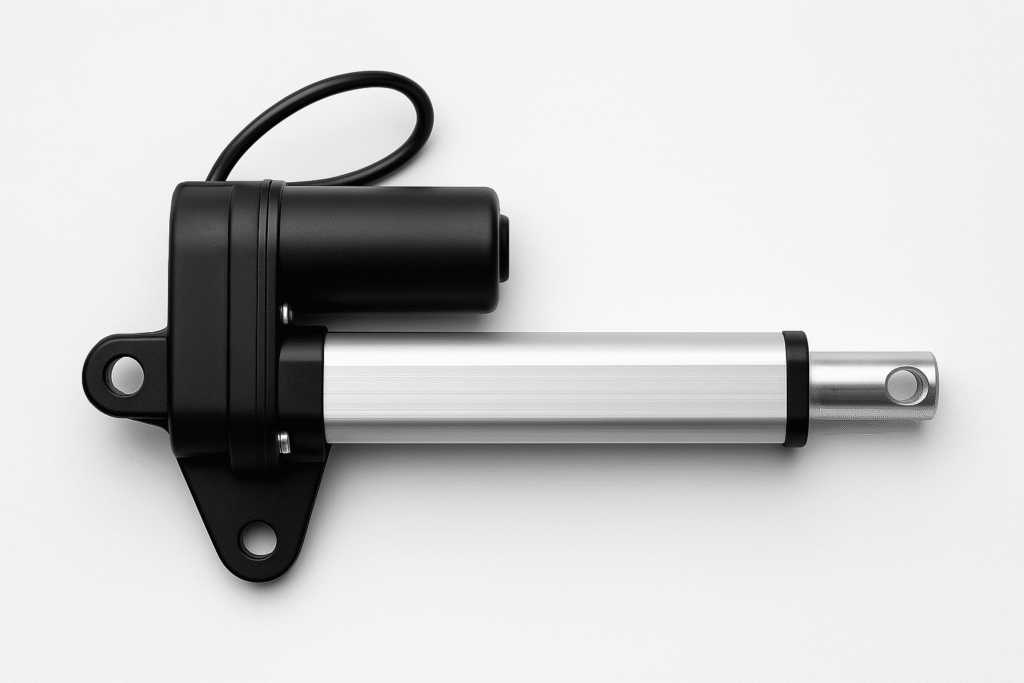

That’s when he stumbled upon a solution: Electric Linear Actuators.

Discovery of a Better Alternative

Rajeev’s engineering head came across an electric linear actuator demo during a machinery expo. Intrigued by its clean operation, compact size, and high precision, Rajeev decided to test a few actuators in their motorized net retraction unit.

What happened next was a turning point.

- Installation was simpler

- No hydraulic lines or compressors

- Smooth movement and silent operation

- Precise control with limit switches and remote control integration

It didn’t take long before Rajeev made the switch across all his products.

A New Era in Sports Equipment Design

Today, Rajeev’s company proudly uses electric linear actuators for:

- Motorized Football Goalposts – Actuators help fold and lift the goal frames effortlessly after practice sessions.

- Basketball Hoop Height Adjustment – Coaches can now adjust hoop height at the press of a button, suiting both junior and senior levels.

- Automated Stadium Seating – Retractable benches and chairs can now be controlled wirelessly during matches and events.

- Cricket Practice Nets – No more tangled ropes or manual lifting. The nets retract neatly using actuator systems.

Benefits They Never Expected

Apart from reducing maintenance costs by over 30%, Rajeev’s team saw a major boost in customer satisfaction. Sports facility managers praised the ease of use, especially during fast-paced tournaments.

More importantly, since electric actuators use no oil or fluid, they are safer and eco-friendly—a huge plus for schools and institutions aiming for green certifications.

Final Whistle: Why Sports Manufacturers Are Adopting This

Rajeev’s story is now a case study for other sports ground equipment manufacturers. As the demand for automation and smart infrastructure grows in Indian and global sports, electric linear actuators are becoming the backbone of modern sports fields.

No more air leaks. No more hydraulic pumps. Just clean, quiet, and efficient motion—one actuator at a time.