In today’s healthcare environment, where efficiency, patient comfort, and safety are paramount, electric actuators have become a game-changer in hospital equipment — especially in medical beds and patient lifting systems. These actuators offer smooth, precise, and quiet motion, making them ideal for critical healthcare applications where reliability and hygiene cannot be compromised.

The Growing Need for Automation in Healthcare

Modern hospitals are shifting from manual systems to automated solutions to:

- Reduce the physical strain on healthcare workers

- Improve patient positioning and mobility

- Enhance safety during transfers and procedures

- Comply with hygiene and operational standards

Electric linear actuators play a central role in meeting these needs.

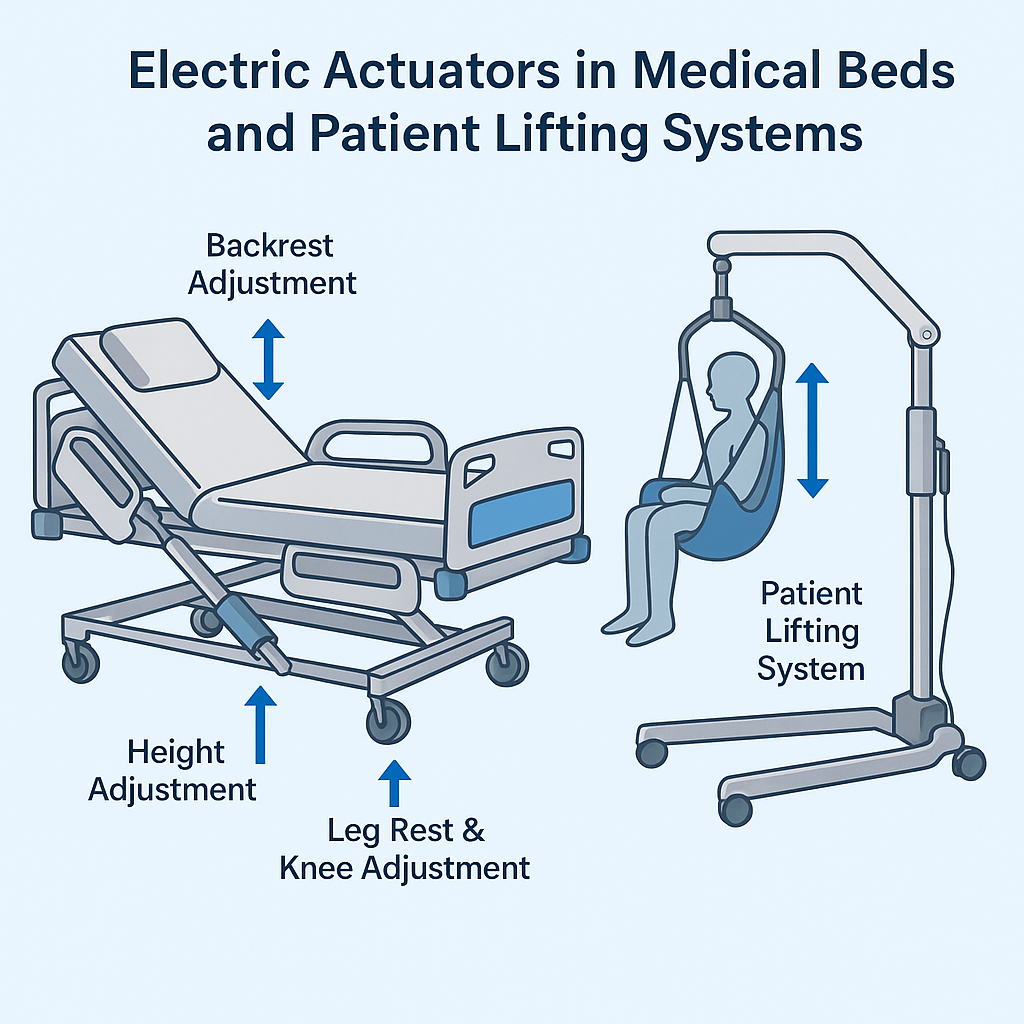

Where Electric Actuators Are Used in Medical Beds

- Backrest Adjustment:

Allows controlled reclining of the upper body, improving patient comfort and aiding medical procedures like feeding or respiratory support. - Leg Rest & Knee Adjustment:

Provides leg elevation to support circulation and reduce swelling in immobile patients. - Height Adjustment:

Helps in raising or lowering the entire bed to assist patient entry/exit and support nurses during treatment. - Trendelenburg & Reverse Trendelenburg Positions:

Enables dynamic positioning for surgical procedures or recovery needs by tilting the bed frame.

With electric actuators, all these movements can be precisely controlled via remote or touch panels, ensuring safety, accuracy, and ease of use.

Electric Actuators in Patient Lifting Systems

For patients who are elderly, disabled, or recovering from surgery, patient lifters are essential to ensure smooth and injury-free transfers between beds, wheelchairs, or examination tables.

Electric actuators make this process efficient through:

- Controlled lifting and lowering

- Smooth horizontal movement

- Fail-safe locking and emergency stop features

These systems are especially useful in ICUs, rehabilitation centers, elderly care homes, and emergency rooms, where frequent lifting is required.

Why Electric Actuators Are the Ideal Choice

- Quiet Operation:

Minimizes disturbance to patients, especially in sensitive environments like ICUs or neonatal wards. - Precise Movement:

Fine control over speed and position for smooth, jerk-free transitions. - Compact Design:

Fits easily within the slim profile of hospital beds or mobile lift frames. - Low Maintenance:

Unlike hydraulic systems, electric actuators are clean, oil-free, and require very little upkeep. - Hygienic and IP-Rated:

Designed to withstand cleaning agents and harsh disinfection processes.

Safety Features Built In

- Overload protection to prevent damage to equipment and injury to patients

- Battery backup for uninterrupted operation during power failure

- Manual lowering function in emergency cases

- Built-in limit switches for stroke control

Future Trends

With the rise of smart hospital beds, electric actuators are now being integrated with:

- IoT sensors for patient monitoring

- Wireless control panels

- Central nurse station connectivity

- Remote diagnostics and fault detection

This means not only better patient care but also increased operational efficiency for hospitals.

Final Thoughts

Electric actuators are transforming the way patient care equipment works. Whether it’s adjusting a hospital bed or transferring a patient safely, these actuators ensure smooth, reliable, and hygienic motion — all while reducing the physical burden on medical staff.

As healthcare systems look toward automation and patient-centric care, electric linear actuators will continue to be the backbone of modern hospital infrastructure.