SolutioNs

This page is a guide to understand the actuator meaning and how they can be used to improve performance and efficiency in industrial processes. We provide expert advice and creative solutions to help you enhance the performance of your machinery and equipment.

Where the Plastic Industry Uses an Innovative Electric Actuator

The plastic and rubber industries need accuracy, speed, and clean production. Because of this, many companies are changing their machines. Instead of hydraulics, they now use electric actuator. Electric actuators give smooth and exact motion. At the same time, they...

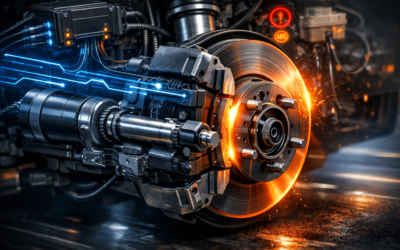

How a Vehicle Brake Is Stopped by using powerful Electric Actuator

Vehicle safety depends heavily on the braking system. However, traditional brakes rely on hydraulic parts. These parts can fail. Therefore, modern vehicles now use powerful electric actuators for braking. In particular, electric actuator play a vital role when the...

Proven Pop-Up Counters with the help of Linear Actuator

Today, smart design is all about saving space. At the same time, users expect comfort and automation. Because of this, pop-up counters using linear actuator are becoming very popular in homes and commercial spaces. These systems allow counters, appliances, or displays...

Revolutionary ETO Cartridge Autoclave Open With The Electric Actuator

Ethylene Oxide (EtO) sterilization is common in medical use. In simple words, it is used when heat is not safe. Because of this, ETO cartridge autoclaves are widely used. At the same time, electric actuator are very important. In fact, they move doors and valves. As a...

Boat Hatch Up & Down Usin Actuator: A Complete Guideg Linear

Opening a boat hatch by hand is not easy. It can also be unsafe on water. Because of this, many boat owners use linear actuator. A linear actuator moves the hatch up and down with a switch. As a result, the hatch opens smoothly and closes firmly. Actuators from...

Frequently Asked Questions(FAQ)

What Applications are Linear Actuators commonly used in?

How can Linear Actuators be used in Robotics and Automation?

Are electric actuators energy-efficient?

Yes, electric actuators are generally energy-efficient due to the high efficiency of electric motors and the ability to control their movement accurately. They consume energy only when actively operating, and their power consumption can be optimized through proper control strategies, resulting in energy savings compared to other actuation technologies.

Are there any maintenance requirements for electric actuators?

Electric actuators generally require less maintenance compared to hydraulic or pneumatic actuators. However, routine inspections, lubrication of moving parts (if applicable), and periodic checks of electrical connections are recommended. It is also important to follow the manufacturer’s guidelines for specific maintenance requirements.

Can electric actuators be controlled remotely?

Yes, electric actuators can be controlled remotely using various methods. They can be operated using wired control signals, such as analog or digital inputs from a controller. Additionally, wireless control options, such as radio frequency or Bluetooth, can also be used for remote actuator control.

What factors should be considered when selecting an electric actuator?

When selecting an electric actuator, factors to consider include the required motion (linear or rotary), load capacity, speed and acceleration requirements, environmental conditions (such as temperature or hazardous areas), power supply availability, control options, and compatibility with the application and system.