BlogS

How Electric Linear Actuators Improve Medical Equipment Performance

In today’s healthcare industry, precision, reliability, and safety are critical. Medical equipment must perform smoothly, quietly, and accurately to ensure patient comfort and correct treatment outcomes. One of the key technologies enabling this level of performance...

Where the Plastic Industry Uses an Innovative Electric Actuator

The plastic and rubber industries need accuracy, speed, and clean production. Because of this, many companies are changing their machines. Instead of hydraulics, they now use electric actuator. Electric actuators give smooth and exact motion. At the same time, they...

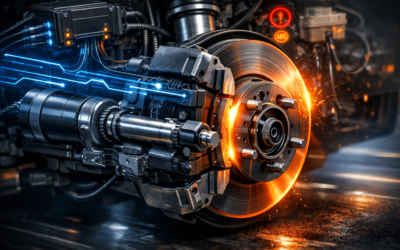

How a Vehicle Brake Is Stopped by using powerful Electric Actuator

Vehicle safety depends heavily on the braking system. However, traditional brakes rely on hydraulic parts. These parts can fail. Therefore, modern vehicles now use powerful electric actuators for braking. In particular, electric actuator play a vital role when the...

Proven Pop-Up Counters with the help of Linear Actuator

Today, smart design is all about saving space. At the same time, users expect comfort and automation. Because of this, pop-up counters using linear actuator are becoming very popular in homes and commercial spaces. These systems allow counters, appliances, or displays...

How Electric Patient Beds Solve Bedridden Patient Challenges?

Caring for a bedridden patient at home is not easy. In fact, families often face daily challenges related to comfort, safety, and hygiene. Moreover, caregivers experience physical strain and emotional stress.However, the right medical equipment can make home care much...

Frequently Asked Questions(FAQ)

What is a linear actuator?

A linear actuator is a device that converts rotational motion into linear motion. It is used to move objects in a straight line

What are the benefits of using a linear actuator?

The benefits of using a linear actuator include precise and controlled linear motion, compact size, easy installation, and efficiency.

How do I install and maintain my linear actuator?

The installation and maintenance of a linear actuator will depend on the specific model and type. Refer to the manufacturer’s instructions for installation and maintenance guidelines.

What safety precautions should I take when working with linear actuators?

Always follow the manufacturer’s instructions and safety guidelines when working with linear actuators. Ensure that the actuator is properly secured and that the power source is disconnected before working on the actuator.

What is the difference between a linear actuator and a rotary actuator?

A linear actuator moves in a straight line, while a rotary actuator rotates around an axis. Linear actuators are used when linear motion is required, whereas rotary actuators are used when rotational motion is needed.

What is the difference between an electric linear actuator and a hydraulic linear actuator?

An electric linear actuator uses electrical energy to create linear motion, while a hydraulic linear actuator uses pressurized hydraulic fluid to create linear motion. Electric linear actuators are typically easier to install and maintain, while hydraulic linear actuators can generate higher force.

Can a linear actuator be used for precise positioning?

Yes, linear actuators are often used for precise positioning due to their ability to provide accurate and repeatable linear motion.

How do I determine the stroke length of a linear actuator?

The stroke length of a linear actuator is the distance the actuator can travel in a straight line. To determine the required stroke length, consider the distance the actuator needs to move to complete its intended task.

What are some common materials used to make linear actuators?

Linear actuators can be made from a variety of materials, including aluminum, stainless steel, plastic, and carbon fiber. The choice of material will depend on the specific application and environmental conditions.

Can a linear actuator be used in hazardous environments?

Yes, some linear actuators are designed for use in hazardous environments and are made from materials that can withstand exposure to extreme temperatures, chemicals, or other hazardous conditions.

Can a linear actuator be customized to fit my specific application?

Yes, many manufacturers offer customized linear actuators to fit specific applications. These can include modifications to stroke length, force, speed, mounting options, and environmental protection.