BlogS

Electric Linear Actuator in Sports Ground Equipment Manufacturer

It all started when Mr. Rajeev, a third-generation entrepreneur running a sports equipment manufacturing unit in Coimbatore, was facing a recurring challenge. His company supplied automated goalpost systems, retractable cricket nets, motorized basketball hoops, and...

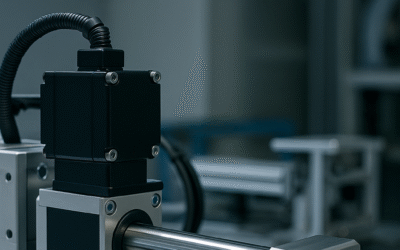

High-Force Electric Linear Actuators for Robotic Impulse Push Applications

When the robotics team at Nexobotics Lab set out to design their latest automation project — a robot that could push objects with short bursts of high force — they faced a mechanical challenge that kept stalling their progress, Electric Linear. The concept was simple:...

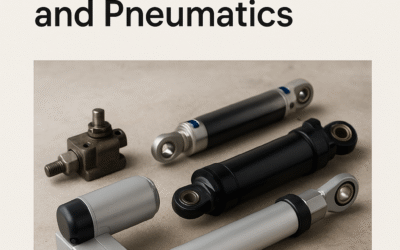

Why Electric Linear Actuators Are Replacing Hydraulics and Pneumatics

A few years ago, inside a mid-sized factory in Coimbatore, a frustrated maintenance engineer named Karthik stood in front of a leaking hydraulic cylinder. Oil had spilled again, production was halted, and workers were waiting idle. This wasn’t the first time. He...

Tilting Boiling Pan Powered by Electric Linear Actuator

In the heart of a bustling commercial kitchen, where every second counts and every movement is calculated, a chef struggled daily with an age-old problem—tilting a massive boiling pan filled with hot soups, gravies, and sauces. The pan was heavy, the movement jerky,...

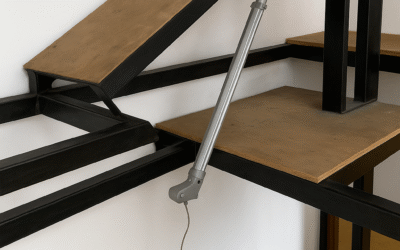

Staircase Door Open & Close Using Linear Actuator

There’s a small electronics lab in Coimbatore run by Aravind, a passionate DIY maker and automation enthusiast. His house has limited space, and he always wanted a neat, hidden storage area that wouldn't eat up extra room or spoil the interior aesthetics, Staircase....

surgical table adjustments using electric linear actuators

In the heart of a bustling hospital in Chennai, a high-stakes surgery was underway. The operating room was filled with focused faces, steady hands, and a patient whose life hung in the balance. Everything was prepped and ready – except for one critical issue: the...

Frequently Asked Questions(FAQ)

What is a linear actuator?

A linear actuator is a device that converts rotational motion into linear motion. It is used to move objects in a straight line

What are the benefits of using a linear actuator?

The benefits of using a linear actuator include precise and controlled linear motion, compact size, easy installation, and efficiency.

How do I install and maintain my linear actuator?

The installation and maintenance of a linear actuator will depend on the specific model and type. Refer to the manufacturer’s instructions for installation and maintenance guidelines.

What safety precautions should I take when working with linear actuators?

Always follow the manufacturer’s instructions and safety guidelines when working with linear actuators. Ensure that the actuator is properly secured and that the power source is disconnected before working on the actuator.

What is the difference between a linear actuator and a rotary actuator?

A linear actuator moves in a straight line, while a rotary actuator rotates around an axis. Linear actuators are used when linear motion is required, whereas rotary actuators are used when rotational motion is needed.

What is the difference between an electric linear actuator and a hydraulic linear actuator?

An electric linear actuator uses electrical energy to create linear motion, while a hydraulic linear actuator uses pressurized hydraulic fluid to create linear motion. Electric linear actuators are typically easier to install and maintain, while hydraulic linear actuators can generate higher force.

Can a linear actuator be used for precise positioning?

Yes, linear actuators are often used for precise positioning due to their ability to provide accurate and repeatable linear motion.

How do I determine the stroke length of a linear actuator?

The stroke length of a linear actuator is the distance the actuator can travel in a straight line. To determine the required stroke length, consider the distance the actuator needs to move to complete its intended task.

What are some common materials used to make linear actuators?

Linear actuators can be made from a variety of materials, including aluminum, stainless steel, plastic, and carbon fiber. The choice of material will depend on the specific application and environmental conditions.

Can a linear actuator be used in hazardous environments?

Yes, some linear actuators are designed for use in hazardous environments and are made from materials that can withstand exposure to extreme temperatures, chemicals, or other hazardous conditions.

Can a linear actuator be customized to fit my specific application?

Yes, many manufacturers offer customized linear actuators to fit specific applications. These can include modifications to stroke length, force, speed, mounting options, and environmental protection.