When the robotics team at Nexobotics Lab set out to design their latest automation project — a robot that could push objects with short bursts of high force — they faced a mechanical challenge that kept stalling their progress, Electric Linear.

The concept was simple: a robotic arm that could deliver a rapid push — strong enough to knock heavy components onto a conveyor, yet controlled enough to reset in milliseconds. Initially, they tried pneumatic cylinders. The speed was there, but the control wasn’t. The response time lagged, and the force was unpredictable under variable air pressure. Hydraulics? Too bulky, messy, and required constant maintenance. That’s when they discovered high-force electric linear actuators.

The Shift to Electric Precision

Electric actuators weren’t new to them — they had used smaller models in pick-and-place arms. But could electric linear actuators handle short, impulsive pushes with high force?

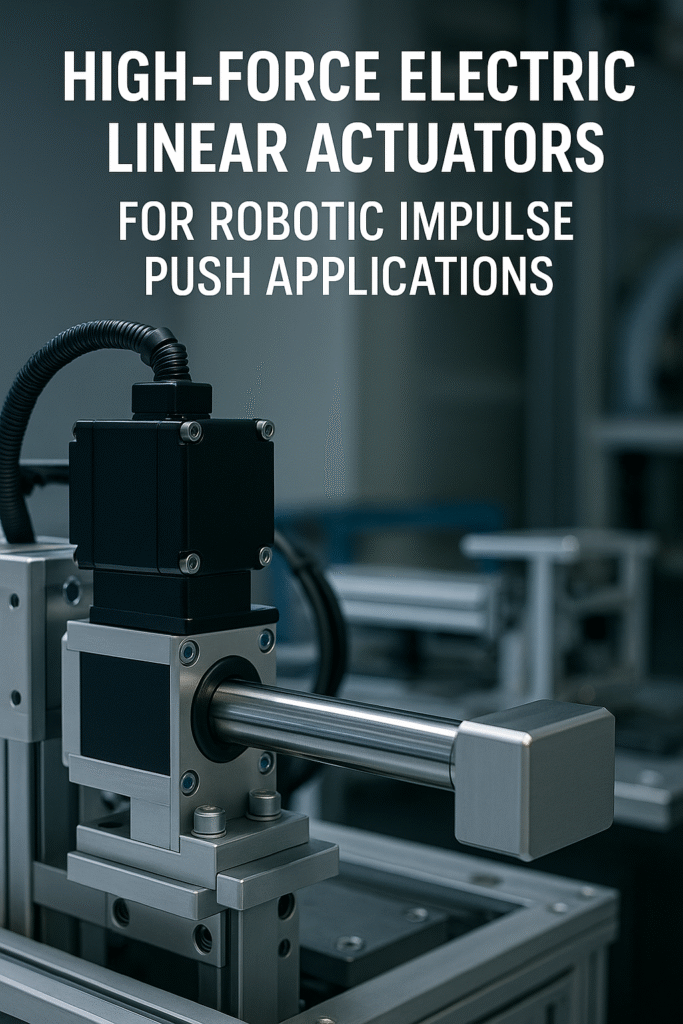

The team partnered with a motion solution company that specialized in electric actuator automation. Together, they selected actuators that combined ball screw mechanisms with servo motors, capable of delivering high peak thrust with tight positional feedback.

Why It Worked

Once integrated, the change was immediate. The actuator could:

- Ramp up force within milliseconds

- Hit targets with repeatable precision

- Retract instantly with zero backlash

- Run silently and cleanly without fluid leaks or compressor delays

The robot was now able to push 12kg parts at high velocity into position with remarkable consistency — and no wasted air, oil, or energy.

The Real Power Behind the Push

This wasn’t just about force — it was about control. The electric linear actuator brought programmable stroke, variable speeds, and adjustable force profiles. Whether the robot had to gently nudge a component or deliver a hard hit, the actuator could be tuned accordingly — all via software.

The team could even add safety limits and overload protection into the system logic, ensuring long-term reliability without fear of damage.

Final Thoughts

The success of this impulsive push application shows how electric linear actuators are quietly revolutionizing robotics — especially in tasks where force, precision, and speed must come together.

For the Nexobotics team, it wasn’t just an actuator upgrade — it was a full system evolution. One that removed guesswork, improved energy efficiency, and unlocked a new level of robotic intelligence.