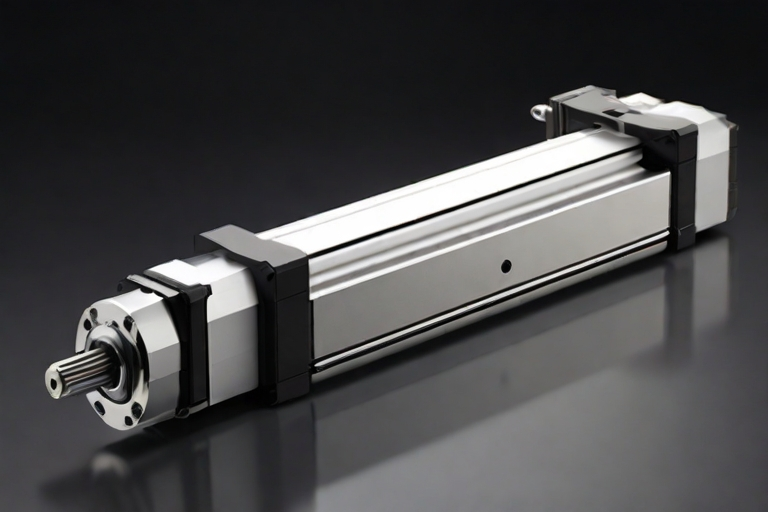

Introduction: In the ever-evolving landscape of automation and robotics, the role of electric linear actuators has become increasingly pivotal. These sophisticated devices are revolutionizing the way we approach motion control, offering a myriad of advantages that span across various industries. In this blog post, we’ll delve into the key advantages of electric linear actuators, shedding light on their impact on precision, efficiency, and versatility in the realm of automation.

- Precision in Motion: One of the standout advantages of electric linear actuators lies in their ability to deliver precise and accurate motion control. Unlike traditional hydraulic or pneumatic systems, electric linear actuators offer finer control, allowing for exact positioning and movement. This precision is particularly crucial in applications where accuracy is paramount, such as manufacturing processes, medical equipment, and robotics.

- Energy Efficiency: Electric linear actuators are known for their energy efficiency, a quality that sets them apart from their hydraulic and pneumatic counterparts. By utilizing electric motors, these actuators eliminate the need for constant power consumption, only drawing energy when in operation. This not only reduces overall energy costs but also contributes to a more sustainable and environmentally friendly approach to automation.

- Compact Design and Space Optimization: The compact design of electric linear actuators makes them an ideal choice in applications where space is a premium. Unlike bulky hydraulic systems, electric linear actuators can be easily integrated into tight spaces without compromising performance. This versatility in design opens up new possibilities for automation in industries with spatial constraints, fostering innovation and efficiency.

- Quiet and Smooth Operation: Traditional hydraulic systems are often associated with noise and vibration, which can be a significant drawback in certain applications. Electric linear actuators, on the other hand, operate quietly and smoothly, providing a more conducive environment for both workers and machinery. This advantage is particularly valuable in settings where noise reduction is a priority, such as medical facilities or precision manufacturing environments.

- Customizable and Programmable: Electric linear actuators offer a high degree of customization and programmability, allowing engineers and designers to tailor their performance to specific requirements. With the integration of advanced control systems, these actuators can be programmed for precise speed, acceleration, and deceleration profiles. This adaptability enhances their suitability for a wide range of applications, from simple linear movements to complex multi-axis operations.

Conclusion: As technology continues to advance, electric linear actuators stand at the forefront of innovation in the field of automation. Their key advantages, including precision in motion, energy efficiency, compact design, quiet operation, and customization capabilities, make them indispensable in various industries. As we look towards the future, the continued refinement of electric linear actuator technology promises to unlock even greater possibilities in the realm of automation and motion control.