In today’s rapidly advancing world, the application of electric actuator has become increasingly significant, particularly in the realm of valve automation. These devices offer precise control, reliability, and efficiency, making them indispensable in various industries. This article delves into the role of electric actuators in valve open/close applications, exploring their working principles, types, and benefits.

What is an Actuator?

An actuator is a device that converts energy into motion. It is a crucial component in various systems, enabling control over mechanical operations. Actuators can be found in numerous applications, from automotive to industrial automation, and are essential for tasks requiring precise control of movement.

Types of Electric Actuator

There are several types of electric actuators, each designed for specific applications. Some common types include:

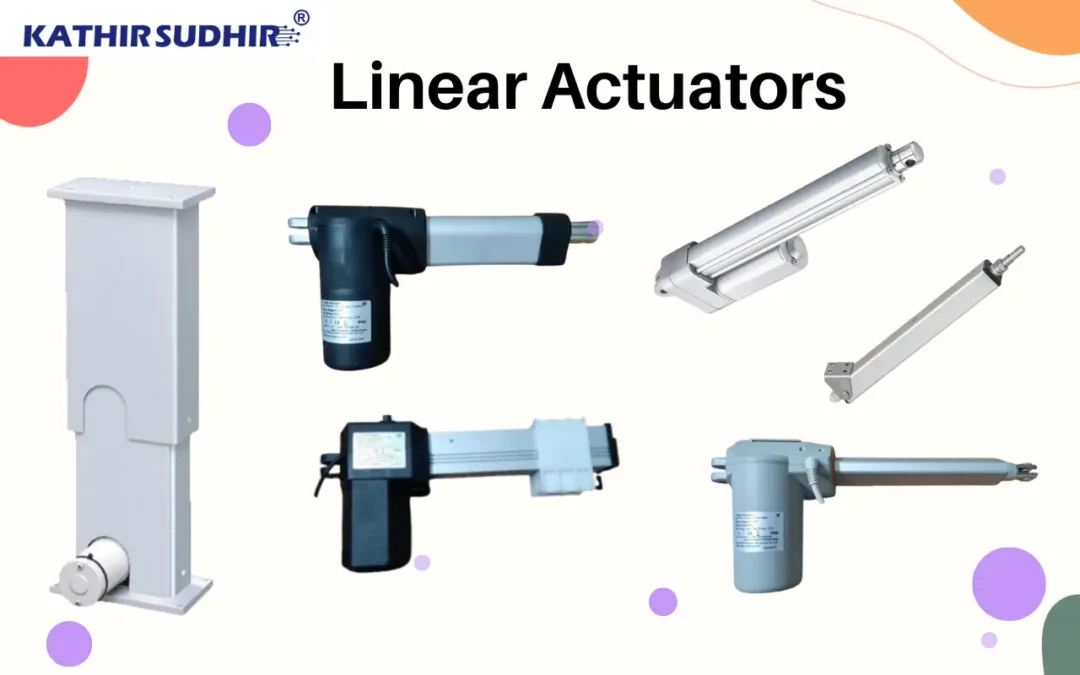

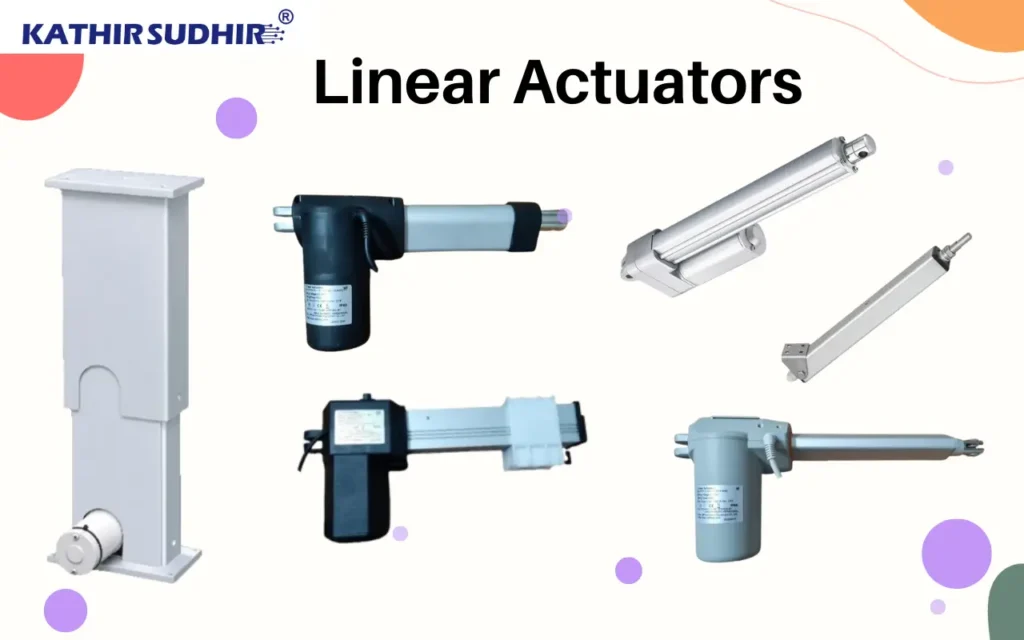

- Linear Actuators: These actuators provide linear motion, making them ideal for applications where push/pull movements are required. Examples include the linear actuator for bed lifts and dental chair electric actuators.

- Rotary Actuators: These actuators produce rotational motion and are commonly used in applications requiring angular displacement.

- Push Pull Linear Actuators: These are specialized linear actuators designed to handle push and pull loads, commonly used in various industrial applications.

How Do Linear Actuators Work?

Linear actuators operate by converting rotational motion into linear motion. This is typically achieved through a screw mechanism, where a motor drives a lead screw, causing a nut to move along the screw’s length. This movement results in the linear displacement of the actuator’s shaft. Linear actuators are often used in applications requiring precise and repeatable positioning.

Electric Actuators in Valve Automation

Electric actuators are extensively used in valve automation to control the opening and closing of valves. This application is critical in industries such as water treatment, oil and gas, and manufacturing, where precise control of fluid flow is essential.

Key Benefits of Electric Actuators in Valve Applications

- Precision and Control: Electric actuators offer precise control over valve positioning, ensuring accurate flow regulation.

- Reliability: These actuators are designed for high reliability, providing consistent performance even in demanding environments.

- Efficiency: Electric actuators consume less power compared to pneumatic and hydraulic actuators, making them more energy-efficient.

Linear Actuator Selection for Valve Applications

Selecting the right linear actuator for a valve application involves considering several factors:

- Load Capacity: The actuator must be capable of handling the load required to open and close the valve.

- Stroke Length: The stroke length should match the valve’s travel requirements.

- Speed: The actuator’s speed should be appropriate for the application, ensuring timely valve operation.

- Environmental Conditions: For applications in harsh environments, IP67 linear actuators are recommended due to their high ingress protection rating.

Electric Actuator Control

Effective control of electric actuators is crucial for optimizing their performance. Advanced control systems, such as actuator control boxes and software, enable precise control and monitoring of actuator operations. These systems often include features like position feedback, which is essential for applications requiring accurate positioning.

Electric Actuator Manufacturers in India

India is home to several reputable electric actuator manufacturers, known for producing high-quality and reliable actuators. Companies like Kathir Sudhir Automation Solutions offer a wide range of electric actuators tailored for various applications, from industrial automation to healthcare furniture.

Applications of Electric Actuators

Electric actuators are versatile and find applications across different industries:

- Healthcare: Used in hospital beds, dental chairs, and treatment couches to provide precise adjustments and improve patient comfort.

- Automotive: Employed in car seat height adjustment and door opening mechanisms.

- Industrial Automation: Utilized in manufacturing processes for tasks such as material handling and machine control.

- Aerospace: Applied in aircraft systems for controlling flaps and other critical components.

Conclusion

Electric actuators, particularly linear actuators, play a vital role in valve open/close applications. Their precision, reliability, and efficiency make them indispensable in various industries. Understanding the working principles and selecting the right actuator for specific applications can significantly enhance operational performance and efficiency. With advancements in technology, the capabilities of electric actuators continue to evolve, offering even greater potential for automation and control.

For those looking to incorporate electric actuators into their systems, it is essential to work with reputable manufacturers to ensure the highest quality and reliability. India’s leading actuator manufacturers provide a diverse range of solutions, catering to the needs of various industries and applications.